| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : EVERSUN

Model Number : ZKJ

Certification : ISO,CE

Place of Origin : CHINA

MOQ : 1set

Price : negotiable

Payment Terms : L/C,D/A,D/P,T/T,MoneyGram,Western Union

Supply Ability : 5000set/year

Delivery Time : within 7-15 work days

Packaging Details : Standard export wooden cases

Function : Conveying material

Material : Stainless Steel

Product Type : Automatic

Features : Dust-free, Low Noise, Easy to Clean

Air Consumption : Varies based on system size

Vacuum Level : Adjustable

Customized Service : Provided

Warranty : 1 Year

Explosion Proof : Optional

Conveying Method : Vacuum suction

Customizable Options : Yes

Product description

The vacuum feeder is a device that realizes the automatic conveying of materials and is widely used in the pharmaceutical, food, chemical and other industries. It can convey powder, granular and other materials from the hopper or container to the designated equipment. The closed conveying design can effectively prevent material dust and cross-contamination, while reducing manual operation, improving production efficiency and cleanliness. It is especially suitable for the handling of materials that are prone to dust, toxic or have strict hygiene standards.

Working principle

The working principle of the vacuum feeder is based on negative pressure adsorption and pressure switching technology:

Firstly, a vacuum environment is created in the closed conveying system by a vacuum pump, forming an internal and external pressure difference.

Then, this pressure difference is utilized to "suck" powder, granules and other materials from the hopper, silo or other containers into the conveying pipeline.

When the materials reach the designated position (such as the feeding port of a mixer, reactor or other equipment), the system switches the valve or stops the vacuum pump to restore the pipeline to normal pressure or convert it to positive pressure. Under the combined effect of gravity and airflow, the materials are detached from the conveying pipeline, completing the unloading.

The entire process is cyclically operated through an automated control system to achieve continuous or intermittent material conveying.

This principle ensures the closedness of material transportation, reduces dust and pollution, and realizes non-contact transportation by means of air pressure difference, which is suitable for the efficient transfer of materials with various properties.

Product features

- Clean and environmentally friendly: Fully enclosed transportation, no dust emission, less pollution, meeting the requirements of high hygiene standards in the industry;

- High efficiency and ease of use: Automated operation, reducing the need for manual labor, improving production efficiency;

- Strong applicability: Capable of transporting various materials such as powders and particles, including fragile and toxic materials;

- Flexible and convenient: Small installation area, flexible pipeline layout, simple operation and maintenance;

- Safe and economical: Reducing material loss, minimizing safety risks, and saving costs.

| Model | Hopper Capacity(L) | Working pressure | Conveying Capacity(kg/h) | Compressed air consumption |

| QVC-1 | 1.1 | 0.4-0.6Mpa | 50-300 | 180NL/min |

| QVC-2 | 6 | 0.4-0.6Mpa | 100-700 | 360NL/min |

| QVC-3 | 12 | 0.4-0.6Mpa | 300-1500 | 720NL/min |

| QVC-4 | 42 | 0.4-0.6Mpa | 600-3000 | 1440NL/min |

| QVC-5 | 60 | 0.4-0.6Mpa | 900-6000 | 2880NL/min |

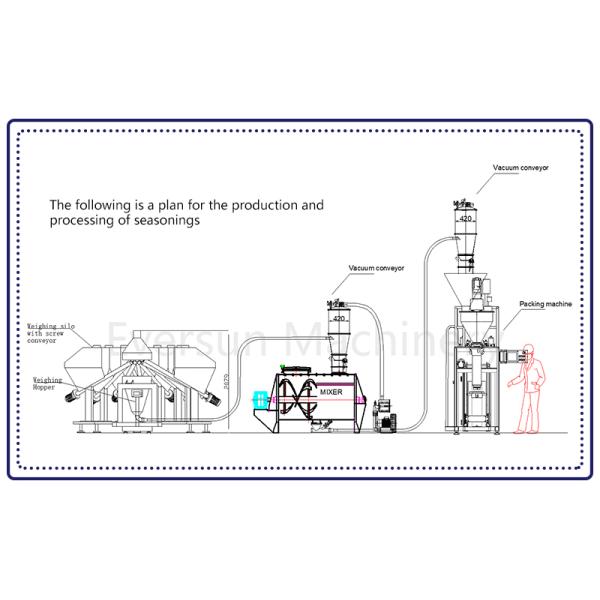

Production line diagram

It works will like the below

1. Put your materials into the weighing silo

2. Enter the required weight of each material in the control system.

3. The ingredient you want will enter the weighing hopper.

4. The weighing hopper is connected with a vacuum conveyor.

5. The vacuum conveyor will suck the material into the mixer

6. After mixing, the material will feed into the packing machine by the vacuum conveyor

7. The packing machine will fill 2kg of material into your bags and seal the bags

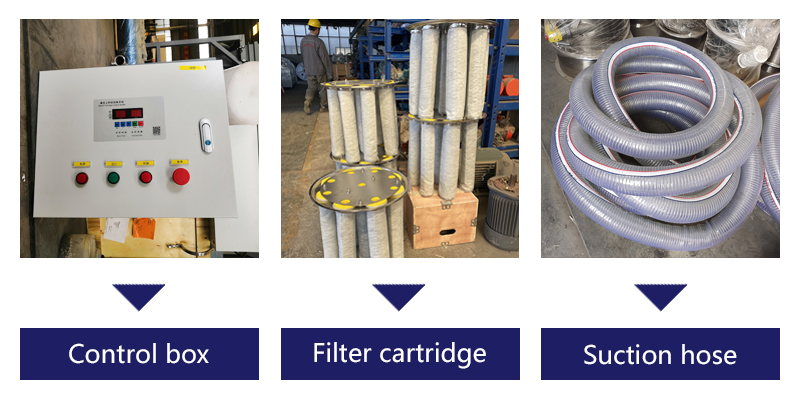

Product details

Product display

Application

Application

Wide range of applications: The vacuum loader is mainly used for conveying powdery and granular materials, such as raw pharmaceutical powders,

chemicalders, metal oxide powders, etc.; however, it is not suitable for conveying overly moist, sticky, or heavy materials.

Packaging & Shipping

Why Choose us

About us

We have been specializing in the production of Screening and conveying equipment for 13 years. China's vibrating screen industry top three. And we have done matching and OEM for many large companies. Including the world's top vibrating screen manufacturer,

Sweco, USA, we have OEM for his China region. And our products are often exported to Australia, Thailand, Indonesia, New Zealand and other countries.

We welcome customers or dealers to visit our factory and will arrange everything for you. Our factory address: West of the industrial and commercial office of Da Zhaoying Town, Xinxiang City, Henan Province.

|

|

Vacuum Conveyor Systems The Perfect Choice for Chemical Food and Pharmaceutical Industries Images |